Hydrogen Sulfide Calibration Gas

Hydrogen Sulfide Calibration Gases

With its colorless, highly flammable, and corrosive properties, Hydrogen Sulfide (H2S) is an extremely hazardous gas that is distinguishable by its "rotten egg" smell. This smell is just the beginning stages of exposure to H2S at around 3-5ppm. Once H2S reaches levels above 30ppm, it takes on a more sickeningly sweet smell. Hydrogen Sulfide's most dangerous properties include its ability to cause olfactory paralysis (the loss of your ability to smell) with exposure over 100ppm and the potential for it to become an explosive with certain exposure levels to other elements such as rust and metal oxides among others.

Breathing this gas is the primary way for exposure to occur, but the detection through the odor alone is not reliable. The presence of this gas occurs with the microbial breakdown of organic materials when oxygen is no longer present and with the breakdown of human/animal wastes. Hydrogen Sulfide is heavier than air, so it typically collects in low lying, enclosed, poorly ventilated regions such as manholes and sewer lines. The monitoring of and early detection of H2S could save your life, so it is important to ensure you know the signs of both short term and long term exposure.

Also known as: Dihydrogen Monosulfide, Dihydrogen sulfide, H2S, Hydrogen Sulphide, Hydrosulfuric Acid, Stink Damp, Sour Gas, Sulfur Hydride, Hydrogene Sulfure, Sewer Gas

Is Hydrogen Sulfide Calibration Gas Reactive?

Hydrogen Sulfide is a highly reactive gas and can become explosive with certain levels of exposure to rust, oxygen, metal oxides, and copper powder among many other materials and chemicals that should be avoided.

Detection of Hydrogen Sulfide: Choosing the Right Hydrogen Sulfide Gas Monitor

At concentrations above 100ppm, a person's ability to smell H2S gas can be lost immediately. Even with its infamous and noticeably foul odor, you should not rely on your sense of smell alone to detect Hydrogen Sulfide. The use of a gas detector is very important in ensuring safety anytime one is working around dangerous gases such as Hydrogen Sulfide. Using a gas monitor that has the capability to alert you in a moment’s notice that gas levels are reaching a dangerous point can mean the difference between life and death. Monitoring air quality is critical when working around any dangerous gas and knowing how to choose the correct gas monitor for your needs in important. A gas monitor equipped with an alert system such as multiple alarms and warning lights can be highly effective with the necessary ongoing maintenance. You want to choose a monitor with rapid response times, sensitivity, and accuracy. The most practical approach is to choose an electrochemical type of H2S sensor detector because it responds in seconds to gas exposure.

Look for a sensor with:

- a rapid response time of 15 seconds or less

- a lower detection limit (sensitivity) of at least 0.5 ppm; 0.1 ppm resolution which is the smallest detectable range and ideally an accuracy of ± 5% over its calibrated range of at least 0-100 ppm

- an accuracy of ± 0.05 ppm at 1 ppm (± 5%) to meet the requirement of a reliable alarm at 1 ppm

- a built-in data logging function for analysis and data collection

- a safe design for use in areas where a combustible atmosphere is imminent at any given time

Health Effects of Hydrogen Sulfide

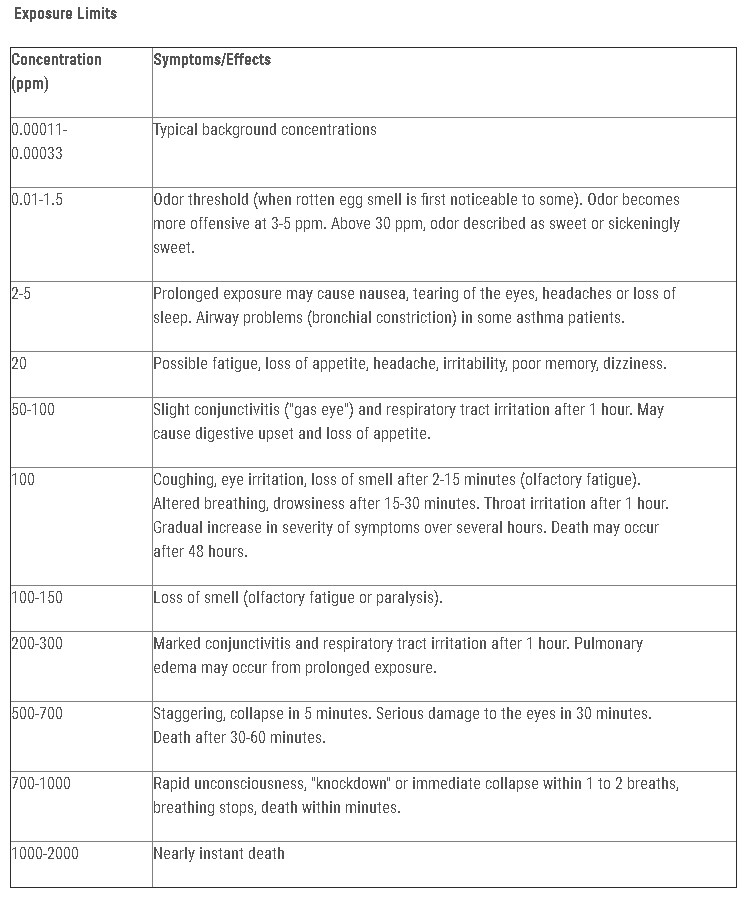

There are a wide range of health effects that can present themselves when a person has been exposed to Hydrogen Sulfide (H2S), and asthmatics are even more at risk. Effects differ depending on the amount of Hydrogen Sulfide gas that was breathed in and the amount of exposure time.

Handling & Storage of Hydrogen Sulfide Gas Cylinders

With the exposure risk of a compressed gas such as Hydrogen Sulfide, proper storage and handling procedures are essential in maintaining a safe work environment. Pressurized chemicals stored in cylinders are released in a gaseous form, therefore any small leak from any part of the system, such as the regulator, can rapidly contaminate a large area. Aside from the risks of chemical leaks, gas cylinders can be physically heavy and run the risk of falling over, breaking important items and causing injury if not secured properly. Hydrogen Sulfide specifically should be kept in a dry, temperature controlled area out of direct sunlight. There should also be no incompatible materials around the cylinder, and when possible, should preferably be stored in a detached building.

- Read hazard labels and follow storage instructions that come with the gas cylinder.

- Always secure gas cylinders upright to a flat surface such as a wall or cylinder rack.

- Do not strap cylinders to other cylinders.

- Gas cylinders should always be tightly chained at or slightly above the midpoint.

- Working conditions should not allow exposure to corrosion, flames, sparks or any other source of ignition.

- Store cylinders in a well-ventilated area with temperatures below 125 ºF.

- Never use compressed gas cylinders for any purposes other then the intended use.

- Pressure regulators with pressure relief devices should only be used.

Author: ChéAna Morgan, Download the article here:https://egasdepot.com/content/Hydrogen Sulfide (H2S)-Calibration Gas.pdf

Hydrogen Sulfide Gas Cylinder Sizes

EGas Depot offers a wide range of Hydrogen Sulfide Calibration Gases. With 10 different liter sizes and 15 different options for your ppm requirements available to you, we are a one-stop shop for all of your field calibration needs.